ANIMAL FEED PLANTS

The concept of the Animal feed plant hereinafter stated as “AFP” is primarily designed for use and processing of raw materials produced in temperate climates, ie, mainly for cereals (and raw materials derived from them), byproducts from rapeseed and sunflower processing and various digestible wastes from meat processing industry, pharmaceutical, fermentation industry, etc.. The production process is continuous and is usually fully automated. Work operation is then limited to monitoring and correction of automated management system, or to cleaning of equipment and its normal alignment.

Control room is a permanent workplace. The quality of produced feed meets the requirements for animal feeding, for whom it is designed, the exact specification is a subject of the contract.

Design of animal feed plants is based on the assumption, that the smooth supply of raw materials is achieved and all materials meet quality standards of feeding industry. Granulation line is a fully integrated part of the AFP technology only in case of universal AFP with capacity of 10t/hod or higher. However it might also be affiliated to smaller production lines, or as subsequently assigned device.

Among the processed materials are cereals, flour components, oil grits and cakes, protein components, and mineral supplements, fat and molasses.for list of implemented animal feed plants see “References”

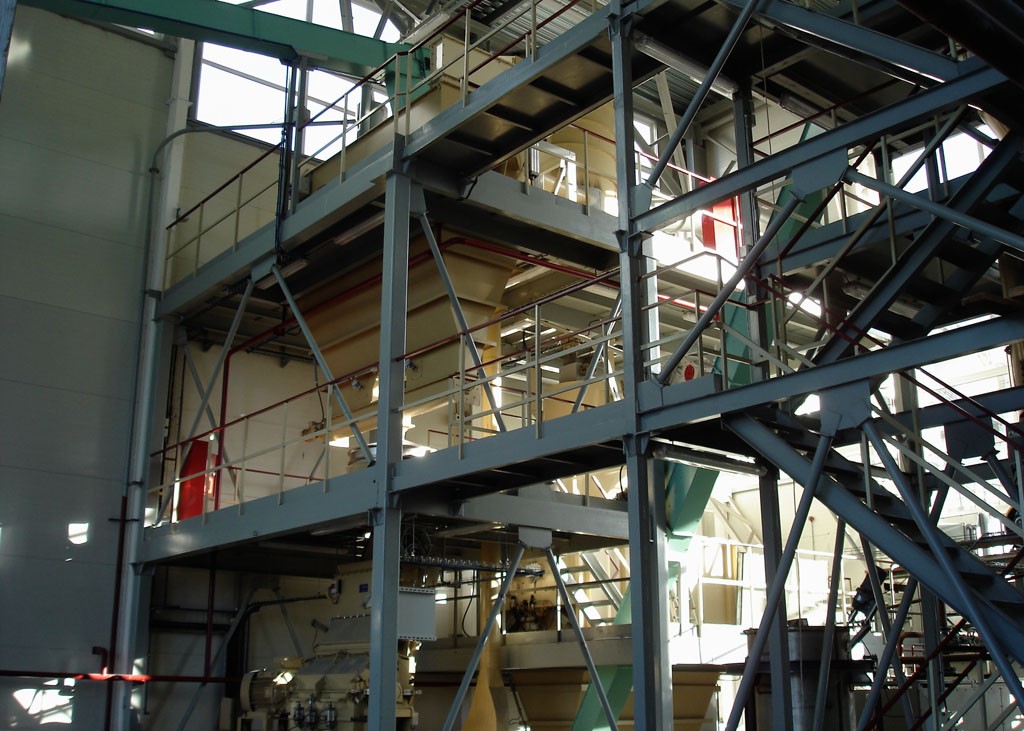

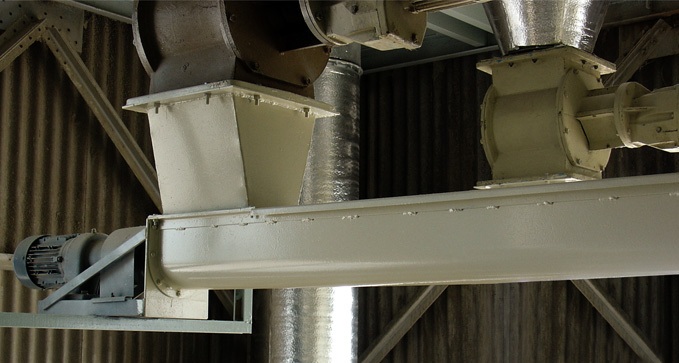

– Example of visual AFP control system