Featured list of implemented contracts is divided into stages and types of technologies. The basic technology of the contract – ie, storage silos, transportation, atc. is performed repeatedly reported in different reference events.

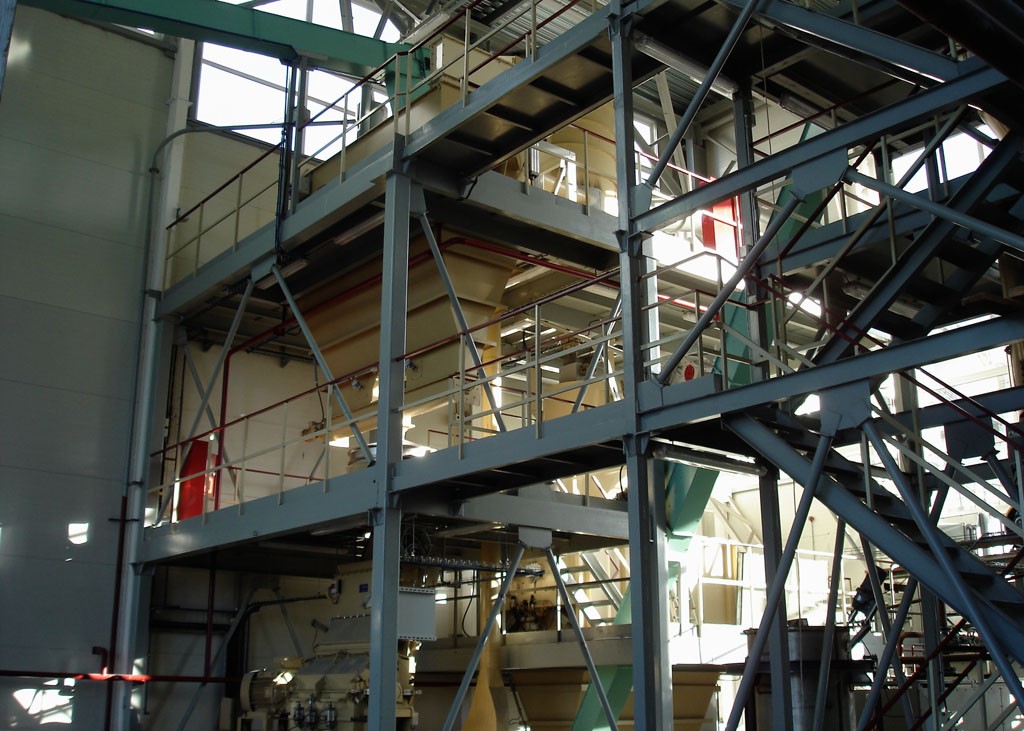

1) CONSTRUCTION OF POST-HARVEST LINES

Osek u Rokycan, Nová Dědina u Uničova, Hlavnice – ZOD, Pikárec, Rozsochy, Lidmovice, Jiřice u Miroslavi, Poběžovice, Brázdim, Velký Ratmírov, Třebětín u Letovic

On these structures we performed a complete supply of technological equipment, steel structures, storage silos (Cordoba + Gruber), design, constructional and technological wiring, control system for technological lines, painting.

2) REPAIRS AND RECONSTRUCTION OF GRAIN SILOS

Grain silos of former AGROPOL network (now AGROFERT network)

| Tagrea a.s. | Čekanice |

| Grana a.s. | Záhoří u Písku, Čimelice |

| Doagra a.s. | Domažlice, Staňkov |

| Agrona a.s. | Nebanice |

| Cerea a.s. | Smiřice, Nový Bydžov, Dobřenice, Libáň, Hlinsko, Jičín, Předměřice |

| Primagra a.s. | Milín, Sedlčany |

| Obila a.s. | Kutná Hora |

| Belagra a.s. | Šakvice, Mikulov |

Grain silos of other companies

| ZZN Strakonice | Radošovice, Vodňany |

| ZZN Louny | Dobroměřice, Vrbno, Žabokliky, Podbořany, Slaný |

| Tekro a.s. | Vráble (SK), Uničov – Nová dědina, Dvory nad Žitavou (SK) |

| Hansa s.r.o. | České Budějovice |

| Strmilov | |

| ZZN Pomezí | |

| Belar a.s. | Lehnice (SK) |

| Hejlov | |

| Hrušovany | |

| ÚKUZ Brno | Lysá nad Labem |

| ZEAS a.s. | Trnov |

| Zemědělské Služby a.s. | Dynín |

| ZZN Mladá Boleslav | Kněžmost |

Repairs and reconstruction of grain silos include:

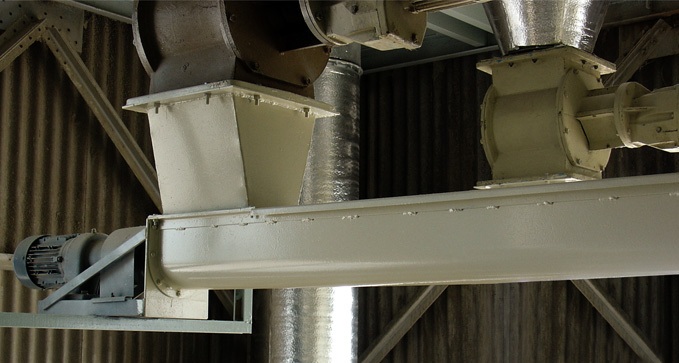

Repair or replacement of transport technology (Redler conveyors, screw conveyors, bucket elevators, aspiration – dedusting cyclones, active ventilation), wiring, control system, project documentation, steel structures, painting, any construction of new reservoirs, truck discharge baskets including discharge basket shelters.

3) RENOVATION AND CONSTRUCTION OF ANIMAL FEED PLANTS

Animal feed plants (AFP) of former AGROPOL network (now AGROFERT network)

| AFP Smiřice | Phase I.-III. |

| AFP Nový Bydžov | Phase I.-III. |

| AFP Čekanice | Phase I.-IV. |

| AFP Záhoří u Písku | Phase I.-IV. |

| AFP Milín | Phase I.-III. |

| AFP Šakvice | |

| AFP Domažlice | |

| AFP Kutná Hora | |

| AFP Jičín | |

| AFP Klatovy | |

| AFP Hlinsko |

AFP´s of other companies

| AFP Jarošov | |

| AFP Radošovice | |

| AFP Pelhřimov | |

| AFP Batelov | |

| AFP Trnov | |

| AFP Strunkovice | |

| AFP Krahulov | |

| AFP Lysá nad Labem | |

| AFP Dynín | |

| AFP Hansa | |

| AFP Stránecká Zhoř | |

| AFP Hrušovany | |

| AFP Hrotovice | |

| AFP Opava | |

| AFP Marefy | Slavkovské krmné směsi |

| AFP Dobroměřice | |

| AFP Kněžmost | |

| AFP Pohledští Dvořáci | |

| AFP Vráble (SK) | Phase I.-II. |

Reconstruction of the AFP includes complete replacement of existing technology in order to increase capacity (15t/hour).

| replacements and modifications | milling lines including hammermills |

| granulation lines including granulation presses | |

| weighting system | |

| wiring | |

| control system | |

| construction of new expedition containers | |

| delivery + construction of steel structures including cladding | |

| new dedusting of transport routes | |

| Modifications of existing bins (storage, granulating and milling) |

4) CONSTRUCTION OF SPECIALIZED PLANTS

Other fodder plants, plants for production of protein concentrates and extruded feeds

| Provimi Pet Food CZ | Brniště Phase I-II. |

| Provimi Pet Food SK | Dunajský Klátov |

| Provimi Pet Food RUS | Klin (Russian Federation) – Phase I. |

| Tekro a.s. | Potoki – (Ukraine), Uničov – Nová Dědina |

| Belar a.s. | Lehnice |

These events included an entire construction of factories (Brniště, Klin, Potoki) – including technology, wiring, steel structures, storage and expedition bins and control system.

Summary of technological elements

Finally we would like to add, that most of the technology is produced by our own capacities (redler conveyors, screw conveyors, bucket elevators, gravity transport elements, flaps, doors). We also produce raw material storage bins (except of Cordoba, Dina or Gruber), steel structures, weights, crossing discharge baskets, shelters, etc.

An annual average production is of approximately:

5000 m of redler conveyers, 30 pcs. of bucketelevators of height about 30m, 600m of screw conveyors, 100 – 250 pcs. doors and flaps (manually, electrically and pneumatically operated)

We use NORD power transmissions for our technological devices, we order about 300 pcs. per year.

The standard warranty period for our products is 24 months, the steel structures + assembly warranty period is 36 months

Installations are usually held in 15-days cycles, but we can adapt to any other system.